WHAT IS PUWER?

CE Marking

Why choose The CE Marking Authority for PUWER assessments?

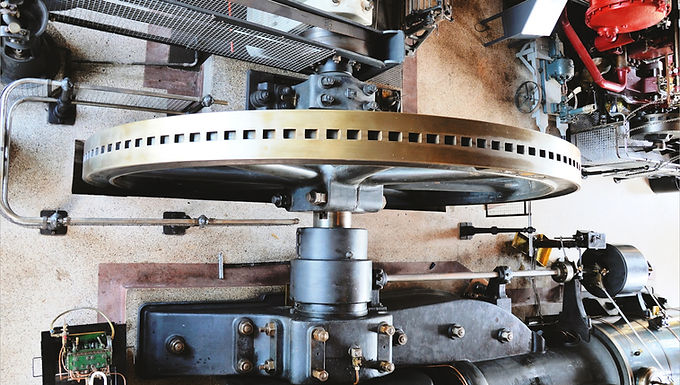

The CE Marking Authority provide comprehensive machinery assessments against the requirements of the Provision of Use and Work Equipment Regulations (PUWER)

As part of our PUWER service we can give advice and assistance on one or all of the following:

Risk Assessments - A legal requirement of the Management of Health & Safety Regulations and the PUWER, and will be carried out in accordance with EN ISO 12100.

A compliance report addressing each of the PUWER requirements in the regulations for each individual machine, This will show conformity or detail any actions needed to demonstrate compliance

Overview

The Provision and Use of Work Equipment Regulations 1998 (PUWER) require users of work equipment to carry out a risk assessment and provide work equipment that is suitable for its intended task and can be used without putting persons at risk. The PUWER Regulations cover any machinery, appliance, apparatus, tool or installation for use at work (whether exclusively or not) - effectively it is anything used at work.

So If you are an employer or self-employed person and you provide equipment for use at work, or if you have control of the use of equipment, then the Regulations will generally apply to you.

PUWER applies to anyone conducting work activities throughout the UK jurisdiction, which means not only the whole of Great Britain's landmass but also its offshore installations such as gas supply platforms, wind turbines and oil rigs.

WHY IS PUWER IMPORTANT?

The 1998 PUWER regulations (updating the original 1992 PUWER Regulations) introduce requirements to ensure that, for reasons of health and safety, inspections are carried out:

Regulation 6 of PUWER requires that where the work equipment is exposed to conditions causing deterioration which is liable to result in dangerous situations, it must be inspected at suitable intervals in order for any deterioration to be “detected and remedied within good time”. The findings of these inspections and any resultant actions taken must be recorded until at least the next inspection.

Equipment must be fully inspected and tested at installation and prior to first use in order to ensure it has been installed correctly and is safe to use. A regime of future inspection and maintenance must then be put in place in accordance with PUWER and any other applicable legislation, taking into consideration risk assessment findings and manufacturer recommendations in terms of equipment inspection and maintenance intervals.

Inspection intervals depend on the equipment type, the associated risks and the particular work environment it is used in as this may cause more rapid deterioration. For example, equipment used outdoors may require more frequent inspection due to weather corrosion factors.

The PUWER requirements state that all equipment that is provided for operation at work must be:

-

suitable for its intended use

-

safe for operation and maintained so as to be always in a safe condition

-

regularly inspected to make sure the machine has been installed correctly and that there is no subsequent deterioration in its condition

-

operated only by personnel who are adequately informed, instructed and trained in its proper use

-

accompanied by appropriate health and safety features that provide protective controls, through devices such as warning lights/sounds and emergency stops, clearly visible markings and sufficient means to isolate the machine from energy sources

Some other types of work equipment are governed by additional specialised health and safety legislation as well as PUWER. These include:

-

PPE Regulations, for Personal Protective Equipment (such as clothing);

-

Pressure Systems Safety Regulations, for pressurised equipment; and

-

LOLER, specifically for Lifting Operations and Lifting Equipment.

If your company is in need of a PUWER assessment, all you need to do to get started is to press the contact button